The quest for cleaner air and more efficient energy systems is an ongoing global challenge. Researchers and engineers have been tirelessly working to develop and perfect technologies that can help reduce emissions and improve overall efficiency. One such technology that has gained significant traction in recent years is air injection technology.

This innovative solution has found applications across a variety of industries, from automobiles to wastewater treatment plants, and is revolutionizing the way we think about air quality and energy conservation.

In this comprehensive guide, we’ll explore the mechanics of air injection technology, its various applications, and the environmental benefits it offers. Join us as we delve into the world of air injection systems and discover how this remarkable technology is clearing the air and paving the way for a greener, more sustainable future.

Air Injection Technology Explained

Air injection technology, also known as secondary air injection or air induction, is a method of introducing additional air into a combustion process to promote a more complete and efficient burning of fuel. This is achieved by injecting air directly into the exhaust stream, allowing unburned hydrocarbons and carbon monoxide to react with the extra oxygen and convert into less harmful emissions like carbon dioxide and water vapor.

How It Works

Air injection systems consist of several key components, including an air pump, air control valves, and an injection manifold. The air pump, which is typically powered by the engine or an electric motor, draws in fresh air from the atmosphere and compresses it. This compressed air is then channeled through the air control valves, which regulate the flow of air into the injection manifold. The manifold directs the air into the exhaust stream, where it mixes with the unburned fuel and other emissions to facilitate more complete combustion.

Applications of Air Injection Technology

Air injection technology has proven its versatility and effectiveness in a variety of industries and applications. In this section, we’ll discuss some of the most common and impactful uses of air injection systems.

1. Automobiles

Perhaps the most well-known application of air injection technology is in automobiles. Internal combustion engines produce harmful emissions as a byproduct of burning fuel. By incorporating air injection systems into vehicle exhaust systems, automakers can significantly reduce the amount of harmful pollutants released into the environment. This technology has become a standard feature in many modern vehicles and has played a crucial role in helping the automotive industry meet increasingly stringent emission standards.

2. Wastewater Treatment

In wastewater treatment plants, air injection technology has proven to be an effective means of promoting the growth of aerobic bacteria, which are essential for breaking down organic matter in the water. By injecting air into the wastewater, treatment plants can maintain optimal levels of dissolved oxygen, ensuring that aerobic bacteria can thrive and effectively process the organic waste. This not only helps to improve the efficiency of the wastewater treatment process but also reduces the environmental impact associated with the discharge of untreated or partially treated wastewater.

3. Aquaculture

Air injection technology has also found a niche in the world of aquaculture, where it is used to maintain optimal oxygen levels in fish farming operations. By providing a consistent and controlled supply of oxygen, air injection systems help to promote the health and well-being of the fish, ultimately leading to higher survival rates and better overall productivity.

4. Industrial Processes

Air injection technology has applications in various industrial processes, such as combustion, incineration, and gasification. In these applications, air injection systems help to improve efficiency, reduce emissions, and minimize the formation of harmful byproducts. By promoting more complete combustion of fuels and other materials, air injection technology can significantly reduce the environmental footprint of these processes while also contributing to more efficient and cost-effective operations.

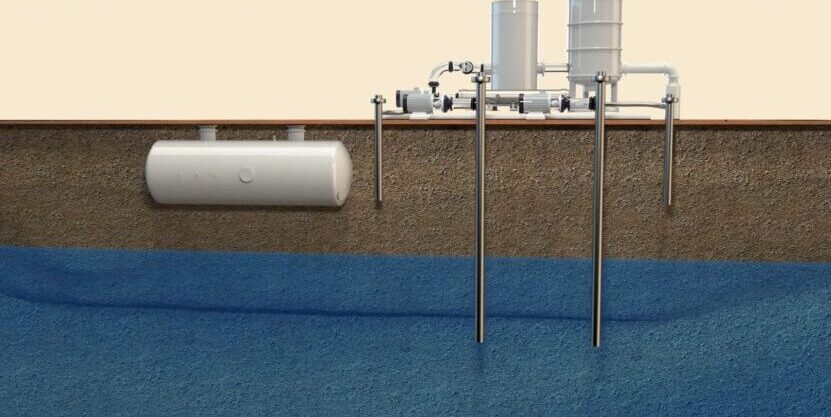

5. Soil Remediation

Soil remediation, the process of removing contaminants and pollutants from soil, can also benefit from air injection technology. In situ, (on-site) remediation techniques, such as soil vapor extraction and bioventing, utilize air injection systems to introduce oxygen into the contaminated soil. This promotes the growth of beneficial aerobic bacteria, which break down the contaminants and restore the soil’s health. This environmentally friendly approach to soil remediation is not only effective but also more cost-efficient than traditional methods that involve excavating and disposing of contaminated soil.

Environmental Benefits of Air Injection Technology

Air injection technology offers a host of environmental benefits that can have a significant impact on the health of our planet. In this section, we’ll explore some of the most noteworthy advantages of this innovative technology.

1. Reduced Emissions

One of the primary benefits of air injection systems is their ability to reduce harmful emissions. By promoting more complete combustion of fuel and other materials, air injection technology can help minimize the release of pollutants such as carbon monoxide, unburned hydrocarbons, and volatile organic compounds (VOCs). This is particularly important in the context of climate change, as reducing emissions is a crucial step toward mitigating the environmental impacts associated with human activity.

2. Improved Energy Efficiency

Air injection technology can also contribute to improved energy efficiency in various applications. By promoting more complete combustion, air injection systems can help to maximize the energy output from fuels and other materials. This can lead to significant energy savings, reducing both operational costs and the overall environmental footprint associated with energy consumption.

3. Enhanced Waste Processing

In applications such as wastewater treatment and soil remediation, air injection technology can improve the efficiency of waste processing, resulting in reduced environmental impact. By promoting the growth of beneficial bacteria and other microorganisms, air injection systems can help to break down organic matter and contaminants more effectively. This, in turn, reduces the amount of waste that needs to be disposed of and minimizes the risks associated with the release of untreated or partially treated waste into the environment.

4. Support for Sustainable Industries

The adoption of air injection technology can support the growth of sustainable industries, such as aquaculture and renewable energy production. In aquaculture, air injection systems can help to improve fish health and productivity, contributing to a more sustainable and environmentally friendly food source. In renewable energy production, air injection technology can be used in conjunction with other technologies, such as biomass gasification, to produce cleaner and more efficient energy sources.

Final Words

Air injection technology is a versatile and impactful solution that is helping to revolutionize industries and pave the way for a greener, more sustainable future. By promoting more complete combustion, reducing emissions, and improving efficiency in a variety of applications, this innovative technology is making a significant contribution to global efforts to combat climate change and protect the environment.

Whether it’s in our cars, wastewater treatment plants, or renewable energy systems, air injection technology is a powerful tool that is helping us to clear the air and create a cleaner, healthier world for generations to come. As researchers and engineers continue to refine and expand upon this technology, the potential for even greater advancements and breakthroughs in air injection systems is virtually limitless.