The energy landscape has been in a state of rapid evolution over the past few decades, with a growing emphasis on clean, sustainable sources and efficient power generation. Amid this transformation, gas turbines have emerged as an increasingly popular choice for power producers around the world.

With their versatility, scalability, and ability to operate in diverse environments, gas turbines have become an attractive option for many applications, from electricity generation to industrial cogeneration.

However, as with any technology, understanding the costs is critical for making informed decisions on investments and implementation. In this comprehensive article, we will delve into the various factors that influence gas turbine costs, the benefits of utilizing them in power generation, and the challenges faced by power producers when opting for this technology.

Factors That Influence Costs

There are several factors that contribute to the overall cost of gas turbines, and understanding these elements is essential for determining the feasibility and return on investment. Some of the primary factors include:

Turbine Size and Capacity

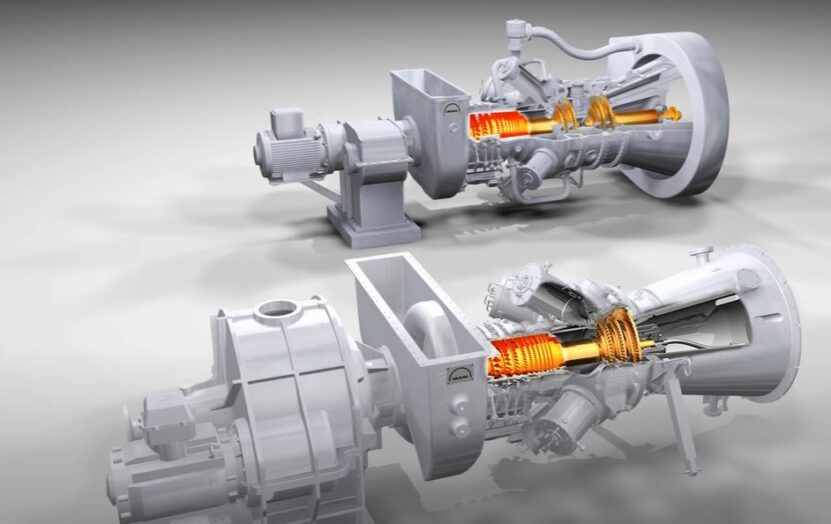

Gas turbines come in a wide range of sizes and capacities, from small-scale units with a few megawatts (MW) of output to large-scale industrial turbines that can produce hundreds of MW. Generally, the cost increases with its capacity, although economies of scale can come into play for larger installations.

Fuel Type

Gas turbines are designed to run on various fuel types, including natural gas, diesel, and even biofuels. The choice of fuel can have a significant impact on the turbine’s cost, as it influences factors such as fuel transportation, storage, and emissions control systems.

Technology and Efficiency

The efficiency of a gas turbine is a critical factor in its cost, as it determines the amount of fuel required to generate a given amount of power. Modern ones are considerably more efficient than their predecessors, with some models reaching efficiencies of 40% or more. However, these high-efficiency turbines come at a higher upfront cost, which must be weighed against the long-term savings in fuel costs.

Installation and Site Preparation

Gas turbine installation costs can vary widely depending on factors such as site accessibility, terrain, and the need for additional infrastructure such as electrical substations or transmission lines. These costs can be particularly significant for remote or difficult-to-access locations.

Operations and Maintenance

Like any complex machinery, gas turbines require regular maintenance to ensure optimal performance and longevity. The cost of maintenance depends on factors such as the turbine’s size, complexity, and operating environment, as well as the availability of skilled technicians and replacement parts.

Benefits of Gas Turbines in Power Generation

Despite the costs associated with gas turbines, there are several compelling reasons for power producers to consider this technology:

Flexibility and Scalability

Gas turbines can be quickly ramped up or down to meet changing power demands, making them an ideal choice for grid support and balancing intermittent renewable energy sources such as wind and solar. Additionally, gas turbines can be deployed as part of a modular power generation system, allowing for incremental capacity expansion as needed.

Lower Emissions

When compared to conventional coal-fired power plants, gas turbines emit significantly lower levels of carbon dioxide (CO2), sulfur dioxide (SO2), and nitrogen oxides (NOx). This can be particularly advantageous in regions with stringent emissions regulations or where carbon pricing is in place.

Fuel Diversity

As mentioned earlier, gas turbines can run on a variety of fuels, including natural gas, diesel, and biofuels. This diversity allows power producers to choose the most cost-effective or environmentally friendly fuel source available, reducing dependence on a single fuel type and minimizing vulnerability to supply disruptions or price fluctuations.

Cogeneration and Combined Cycle Applications

Gas turbines can be utilized in cogeneration or combined cycle power plants, where waste heat from the turbine is captured and used to generate additional electricity or provide thermal energy for industrial processes. This approach can significantly increase the overall efficiency of the power plant, leading to lower fuel consumption and reduced emissions.

Shorter Construction Times

Gas turbine power plants typically have shorter construction times compared to other types of power generation facilities, such as nuclear or large-scale coal-fired plants. This can lead to faster returns on investment and reduced financial risks associated with lengthy construction periods.

Challenges in Implementing This Technology

While gas turbines offer numerous benefits, there are also several challenges that power producers must contend with when considering this technology:

Capital Costs

The upfront costs of this technology can be higher than those of other power generation options, particularly for high-efficiency models or large-scale installations. This may deter some power producers from pursuing gas turbine projects, especially in regions with low electricity prices or limited access to financing.

Fuel Price Volatility

Gas turbine operating costs are heavily influenced by fuel prices, which can be subject to significant fluctuations over time. This volatility can make it difficult for power producers to accurately forecast long-term operating costs and may necessitate the implementation of hedging strategies to mitigate the financial risks associated with fuel price swings.

Regulatory and Environmental Considerations

Although gas turbines generally have lower emissions than traditional coal-fired power plants, they still produce greenhouse gases and other pollutants. Power producers must navigate a complex web of local, national, and international environmental regulations, which can add to the cost and complexity of gas turbine projects.

Skilled Workforce and Maintenance Challenges

Gas turbine technology requires a skilled workforce to operate and maintain the equipment, which can be a challenge in regions with a limited pool of qualified technicians. Furthermore, the need for specialized maintenance and replacement parts can lead to higher long-term operating costs, particularly in remote or isolated locations.

In a recent study exploring the future of energy generation, researchers discuss how renewables can offer a reliable baseload power solution, fundamentally reshaping the energy landscape.

Closing Thoughts

As the global energy landscape continues to evolve, gas turbines are poised to play an increasingly important role in power generation. While the costs associated with this technology can be significant, the benefits of flexibility, fuel diversity, and lower emissions make them an attractive option for many power producers.

Understanding the various factors that influence gas turbine costs, as well as the challenges and benefits associated with this technology, will allow decision-makers to make informed choices about the role of gas turbines in their power generation portfolios. With continued advancements in this technology and a growing focus on sustainable energy solutions, the future of these turbines in power generation appears bright.